Wanna build a Food Truck? Hot Dog Cart? Great!

Before you build or modify unit verify what codes you must follow to get your permit.

Codes vary by local health departments, not state, and we do not know this information.

My health department doesn't care, they won't look...

We hear this many times and then get the call needing a different tank send over-night to meet a deadline.

To save YOU time and money check first.

The person who built my food truck said the inspector won’t care.

This is incorrect information from the builder and often after you have already paid for parts and services you are stuck paying for new items and installation, check first and ask that correct items be included in the build before beginning a project.

Example of how difficult getting a mobile food unit permit can be, check first and get approval.

What to ask on Fresh and Gray Water Tanks

Size (Gallons / Measurements) Health Departments require Gray tank to be larger than Fresh

Fittings (Size / Placement / Materials)

Filling Procedure (Lockable Fill Dish / Materials)

Tank Placement (Inside / Outside of unit)

Clean Out Requirements

Water Tank Calculation Examples

Multiply (fresh tank size) x 1.15 (1 . 15%) = Tank needed

30 x 1.15 (15%) = 34.50

30 x 1.50 (50%) = 45

FREE RESOURCES

ServSafe Manager Practice Tests --- These are for practice only current tests will vary.

NYC Health Department - Free Online Course

State Food Safety - Disaster Relief Food Safety Training

CDC Center for Disease Control Food Safety Videos

Iowa State University of Science and Technology - Food Service Employee Training Videos

EXAMPLES OF MOBILE FOOD UNIT TERMS

These are examples of terms and requirements that you may encounter.

ALWAYS check your local health department where the inspection will be made for requirements.

Mobile Food Unit: Any vehicle that is self-propelled or that can be pulled or pushed down a sidewalk, street, highway or waterway, on which food is prepared, processed, or converted or which is used in selling and dispensing food to customers. Mobile food units must be capable of being mobile at all times during operation. The wheels of the unit may not be removed from the unit at the operating location. Most mobile food units require a commissary for rapidly cooling foods, food washing, overnight storage, and dish washing facilities. Check local codes for requirements.

Unattended Mobile Food Unit Prohibited: No MFU shall be parked on the street overnight or left unattended and unsecured at any time food is kept in the MFU. Any MFU which is found to be unattended in this manner shall be considered a public safety hazard and may be ticketed and impounded. Additionally, after a Vendor is done operating on private property for the day, the MFU must be relocated to a site other than the private property on which it was operating, unless that private property is also the commissary for the MFU.

Plan Review: Conducted by the Regulatory Authority by reviewing the menu, equipment list, and layout of the unit for several reasons; 1) To make sure the unit will be in compliance with the regulations, 2) to prevent any misunderstandings by the applicant/owner, and 3) allows the RA to become familiar with the operation, the owner, and potential for future problems before the unit is permitted. Check local codes for requirements.

Identification: Each mobile food unit must be clearly marked with the licensee's name or a distinctive identifying symbol. Check local codes for requirements.

Water Supply: Mobile food units must use water from an approved water supply and be designed to provide a sufficient capacity to meet operational needs. The system must be of sufficient capacity to furnish enough hot and cold water for food preparation, dish washing, and hand washing. Materials used in the construction of mobile food unit water tanks and plumbing must be made of safe (food or drinking water grade) materials. All connecting hoses must be food grade and clearly identified as to their use (so as not to be mistakenly used for another purpose). A backflow prevention device must be installed at one hose connection bib to prevent backflow into the clean water system. Check local codes for requirements.

Sewage Disposal: All liquid wastes must drain into an approved wastewater tank. All liquid waste from the waste tank or from cleaning activities such as cleaning the mobile food unit must be captured and properly disposed of in the sanitary sewer. Wastewater can not be dumped onto the ground, onto the streets, or into a storm a drain. Check local codes for requirements.

Power Source: Mobile food unit must have an appropriate power source (e.g., generator or plugged into an electrical source) to ensure food sanitation requirements are met at all hours of operation (e.g., provide proper cold holding, hot holding, and meet hand washing and dish washing hot water requirements). Check local codes for requirements.

Hot Water: Hot water generation and distribution systems must be sufficient to meet the peak hot water demands for hand washing facilities, dish washing, and other operations of the mobile food unit. Check local codes for requirements.

Hand Washing Facilities: The location of hand washing facilities must be convenient and readily accessible to all operations. Mobile food units must have plumbed hand washing facilities with water under pressure. The use of hand washing facilities is restricted to hand washing only. A splash guard around the handsink to prevent splashing cross contamination. Check local codes for requirements.

Dish Washing: All utensils and equipment must be washed in a 3-compartment sink (capable of washing the largest utensil or equipment) or commercial dishwasher. Check with local code for smaller units that do not have dish washing sinks. Check local codes for requirements.

Indirect Waste: Any piece of equipment utilized to hold food or ice that is equipped with a drain must have indirect waste plumbing. Check local codes for requirements.

Potentially Hazardous Food: A food that is natural or synthetic and is in a form capable of supporting the rapid and progressive growth of infectious or toxigenic microorganisms, or the growth and toxin production of clostridium botulinum. “Potentially hazardous food” includes an animal food that is raw or heat-treated, a food of plant origin that is heat-treated or consists of raw seed sprouts, cut melons, and garlic and oil mixtures. Check local codes for requirements.

Food Handler Cards: All food service workers who handle food, drinks, or utensils must have a valid Food Handler Card. Check local codes for requirements.

Food Sources: All foods, beverages and ice must be obtained from an approved source. Any food preparation or food storage done off-site must be accomplished at a licensed food establishment. No home prepared or home canned foods or foods that have been stored in a home are allowed. Check local codes for requirements.

Cold Holding: Adequate refrigeration must be provided to ensure potentially hazardous foods are held at correct temperature. Each refrigeration unit must be equipped with either a built-in thermometer or be provided with a numerically scaled spirit stem thermometer. Thermometers must be located to measure the air temperature in the warmest part of the refrigerator and located in an area where the thermometer is easy to read. Check local codes for temperatures.

Hot Holding: Adequate equipment to hold hot potentially hazardous food must be provided. Check local codes for temperatures.

Rapid Cooling: The best way to keep food safe is to make it fresh each day, just before you serve it. If you have food that is leftover or made in advance, you must cool this food rapidly at a facility with equipment designed for rapidly cooling foods. Check local codes for temperatures.

Rapid Reheating: Potentially hazardous food that has been cooked, cooled, and reheated for hot holding must be reheated with appropriate methods and heating - Check local codes for temperatures.

Probe Thermometer: Check local codes for requirements.

Date Marking: Ready-to-eat potentially hazardous foods that will not be used within a day must be date marked with either the preparation date, use-by date, or date the commercial package was open. Check local codes for requirements.

Storage: Adequate storage equipment is required to assure that all food, food containers, and single service utensils are stored at least six inches above the floor, or on a four inch high platform (or wheeled platforms). Storage shelves must be smooth, impervious, and easily cleanable. Food may not be stored in areas such as under sinks with exposed or unprotected sewer lines or water lines. Toxic items must be stored and labeled to allow for proper use and prevent contamination of food and food contact surfaces. Check local codes for requirements.

Auxiliary Storage: Auxiliary storage is limited to items necessary for one day of operation. Auxiliary storage must be in impervious, nonabsorbent, covered containers and stored in a way that prevents contamination and meets food safety requirements. Check local codes for requirements.

Produce: Produce must be washed at a licensed facility in a sink with indirect waste. Check local codes for requirements.

Equipment: All equipment should be easy to clean and maintained in good repair. All metal equipment should be free of rust and corrosion. Rusty/corroded metal equipment should be replaced or refinished in an approved manner. Wooden surfaces must be finished to provide a washable surface. All stationary equipment should be installed to allow easy cleaning beneath and/or behind equipment. Check local codes for requirements. Documents of Approved Appliance Testing.

Self-Service: Self-service foods within customer reach that are not prepackaged must be protected from customer contamination by a sneeze shield or other approved means. Condiments such as ketchup containers and salsas must be dispensed to protect foods from contamination. Condiments must be dispensed from the mobile food unit. Auxiliary storage may not be used for self-service, assembly, or preparation activities. Check local codes for requirements.

Ventilation: Adequate ventilation is required to prevent grease or condensation from collecting on walls and ceilings. Please check with local city and/or county building and fire departments regarding requirements. Do I need a Fire Inspection? Fire Extinguisher? Ancillary Fire Suppression System Check local codes for requirements.

Wall, Floor, and Overhead Protection: Floors, walls, and ceilings must be finished, smooth, and easily cleanable. All outer openings must be protected to prevent the entrance of insects, rodents, and contamination from weather elements.

Overhead protection must be provided for mobile food units that are operated outdoors and where food is not covered at all times. Examples of overhead protection include roofing, ceilings, awnings, or umbrellas. Overhead protection is not required for barbecue units that have a lid or covering that will protect foods from contamination. The overhead protection must be maintained in good repair. Check local codes for requirements.

Lighting: Adequate lighting must be provided. Light bulbs must be shielded or shatter resistant. Check local codes for requirements.

Doors and Windows: Exterior doors must be rodent proof (clearance may not exceed 1/4 inch and should be as tight-fitting as possible). All openings to the outer air must be screened to prevent fly entry. Check local codes for requirements.

Employee Personal Items: Employee personal items such as jackets, purses, medicines, etc., must be stored separately from food preparation areas and in a manner to prevent contamination. Check local codes for requirements.

Garbage Disposal: Must be disposed of at an approved, sanitary garbage disposal site or at base of operations. Garbage facilities at the base of operations must be located in an area with a hard, nonabsorbent surface such as cement or asphalt. Outside containers must be covered and adequately sized. Check local codes for requirements.

Hazard: A biological (microorganism), chemical (cleansers, pesticides), or physical (fingernail, plastic) property that may cause an unacceptable consumer health risk. Check local codes for requirements.

Smokefree Workplace Law: Check local codes for requirements.

30 Day Return Policy

Shipping Information

Water Tank Sizes

Custom Tanks

Tank Fittings

Plumbing Examples & Available Products

Monitor Panels & Water Tank Probes

Water Pumps

Waste Water Tanks & Help

Customer will need to return all merchandise in new, unused condition and packing materials if available.

To return item customer will need to pay return shipping. Packages refused or return to sender will not be delivered back and no credit/refund will be issued.

1130 County Road 6 West

Elkhart, IN 46514

Phone: 574-206-0101

Return Process

This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes to return the correct item. We'll notify you via e-mail of your refund once we've received and processed the returned item.

~ Food Vendors ~

Before you build or modify unit verify rules and regulations.

Codes vary by local health departments, not state.

Forward the documents and tank information provided to your local health department before purchasing to be sure these tanks will pass your local inspection, this is your responsibility.

** Kentucky Requires the NSF Logo to be molded in the tank, we do not offer NSF Logos in the tanks due to NSF changing the fees wanting each item certified. Tank & Fittings made from DOW NSF International NSF/ANSI Std 61 approved Medium Density Polyethylene (MDPE) Resin - this is NSF Approved and Certified Material. Very with your state if the same code applies.

Size (Gallons / Measurements / Fresh to Gray ratio)

Fittings (Size / Placement / Materials)

Filling Procedure (Lockable Fill Dish / Materials)

Tank Placement (Inside / Outside of unit)

Clean Out Requirements

Water Tank Percent Calculation Examples

Multiply (fresh tank size) x 1.15 (1 . 15%) = Tank needed

30 x 1.15 (15%) = 34.50

30 x 1.50 (50%) = 45

We do not recommend sizes or verbally give measurements please look at the Water Tank List located at the top of each webpage to see all tanks Class A Customs currently manufactures.

What fittings will I need for my plumbing?

This will depend on how you are setting-up your tank and will vary by application, we are not aware of what items you will be needing, please view the Plumbing Examples & Available Products

Be sure to Sanitize Tank before installing.

My health department doesn't care, they won't look... my builders said it is ok...

We hear this and then get the call needing a different tank sent overnight to meet a deadline. It takes very little time to verify requirements, this saves you time and money. Forward the documents and tank information provided to your local health department asking them if these will work.

Build A Food Truck Helpful Video Series

~ Fresh and Gray Water Tank Information ~

BPA FREE Class A Customs does not carry this chemical nor uses it in the manufacturing process

NSF CERTIFIED MATERIALS Tank & fittings made from DOW NSF International NSF/ANSI Std 61 approved Medium Density Polyethylene (MDPE) Resin

U.S. FDA 21 CFR 177.1520 (c)3.1a

Canadian HPFB No Objection

Underwriters Laboratories Inc.

EU, 10/2011

NSF International NSF/ANSI Std 61 (sec 4 & 5)

FRESH OR GRAY WATER USE ideal for rvs, food vendors and extra water storage

COLOR Creamy White in color so you can see waterline through tank

MADE FROM Medium Density Polyethylene (MDPE) Resin - glues do not stick to this material and easily cleaned.

The tank looks like the side is bowed, is it safe?

Due to the manufacturing process all the tanks especially the larger in size will have a bowing to the walls, when the tank is filled the tank will expand out removing the inward bow, we recommend laying all tanks on a level surface (this can be angled) and bracing the tanks. For larger tanks it is recommended to brace all side walls with plywood or metal, we do not recommend using ratchet straps on the tanks alone as this is a large amount of weight on a thin strip and may cause cutting into the tank.

I have only so much room how many gallons can I get in that space?

We do not recommend sizes or verbally give measurements please look at the Water Tank List located at the top of each webpage to see all tanks Class A Customs currently manufactures.

How are the water tanks measured?

Please be sure to look at the photos provided with each item as measurements and fitting placements will be included. Measurement of the tanks do not include the fittings, this will add extra length to the tank.

Do you have a list of water tanks used in vehicles?

Unfortunately we do not have a list or way to cross reference what tank you have or had in your unit when manufactured, check with the vehicle manufacturer or look for part number on tank.

Do you know if someone has used a _____ tank in a ______ ?

No, we do not have a list of vehicles, uses or projects people have done with our tanks.

Other Water Tank Suppliers

~ Fittings ~

At this time Class A Customs only installs the following fittings into our Fresh / Gray tanks

.5" NPT Female

1.5" NPT Female

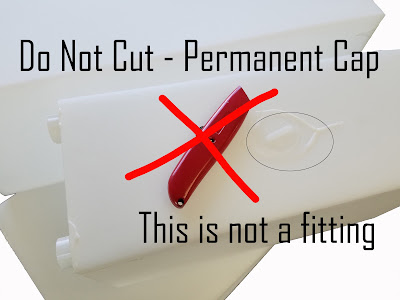

1.25" Outer Diameter x 2" Long Smooth Pipe / Boss Fitting (glues does not stick to pipe, it can not be sealed or capped)

If you are a manufacturer or OEM needing custom fittings please contact sales for more information, minimum quantity of 50 tanks will apply.

What fittings will I need for my plumbing?

We are not aware of how to set-up your tank, set-up will vary by each application this is something you need to research. Have a certified technician install all parts to prevent product damage and personal injury. Please view our Plumbing Category for information on loose fittings we carry.

There is glue flaking on my tank!

No glues or sealants are used to install the fittings, the residue left by putting the fittings in place is part of the material the tanks and fittings are made from and may spider crack or flake off over time, this in no way harms the tank or causes any usage issues.

Blank Tanks (no fittings installed) are available but due to customer confusion we have removed them from the online store.

If you are wanting a Blank Tank please note this in the customer comments section of the order when checking out, this will add up-to 7 days to the lead time.

Example: On my order Tank T-1800 is a BLANK TANK all other tanks have fittings. Thanks --- OR ---- All Tanks Blank Tanks. Thanks

Can I cut a hole in the tank and glue another fitting in?

No, fitting are spun welded into the tank, friction between the fitting and the tank causes both to melt and permanently seal, no additional glues or sealants are used to install the fittings.To add fittings or repair a damaged fitting we now offer Uniseal Fittings, please watch the included video for information.

What fittings will I need for my plumbing?

We are not aware of how to set-up your tank, set-up will vary by each application this is something you need to research. Have a certified technician install all parts to prevent product damage and personal injury. Please view our Plumbing Category for information on loose fittings we carry.

Be sure to Sanitize Tank before installing.

It is recommended to use plastic NPT male fittings with plastic female NPT fittings to avoid damaging the threads, metal thread fittings can crush the plastic threads.

All water tanks we carry must be vented, they are not pressurized tanks.

Have a certified technician install all parts to prevent product damage and personal injury.

Tank must have a large enough opening for air to freely move in and out of tank, this is called "venting" the tank. If tank is not properly vented tank will explode when filled or implode when emptied.

A garden hose is a pressurized water line, do not make a secured connection to the water tank with a pressurized line. Tanks need to be gravity feed, this allows for air to escape while the water is going into the tank. Our Basic Plumbing Diagram shows how an RV or food unit can be set-up using a gravity fill dish.

For my application I am going to use a pressurized line to the tank.

This will void any warranty on the tank. Turning a garden hose on half way does not work because you can control the amount of water flowing but not the pressure in the line, leaving the tank to fill risks exploding the tank.

What is a fill dish?

The fill dish is located on the outside of your unit so that you can easily add water to your tank without the need of opening a compartment or climbing under your unit. You can find the fill dishes in the Plumbing Category.

For adding water to the Water Tank you need a Gravity Fill Dish, the hose rests in the port it does not screw onto the port this allows you to place a garden hose into the Gravity Fill Dish port without making a sealed connection so the supply is not pressurized.

For using Water Directly from a garden hose you need a City Fill Dish, the hose makes a sealed connection and the water supply is pressurized, you can not hook this to your water tank and you do not need to go through your water pump.

We carry Gravity Fill Dishes, City Fill Dishes and Combo Fill Dishes that have both gravity and city, the benefit of having both is you can have a water tank of fresh water but if you go to a location that supplies pressurized water (campground - fair - etc.) you do not need to use your water tank supply of water you can simply use the water provided. Be sure to look at the provided example plumbing diagram for more reference.

For my application I am not using a fill dish.

For gravity feeding you can place a larger fitting such as a PVC elbow in the tank and allow your hose to rest in this when filling, not making a secured connection as this would then be pressurized.

You would still need to vent the tank, this can be as easy as placing a fitting with a screen secured over it. Be aware that if you overfill the tank the excess water will exit the vent fitting, placing the vent fitting overflow to an outside location is recommended.

Be sure to screen over the vent fitting overflow to prevent anything from entering the tank. Do not over-tighten fittings as damage will occur.

Examples of Items to Vent Tanks - We do not sell these products they can be found online

What fittings will I need for my plumbing?

We are not aware of how to set-up your tank, set-up will vary by each application this is something you need to research. Have a certified technician install all parts to prevent product damage and personal injury. Please view our Plumbing Category for information on loose fittings we carry.

Be sure to Sanitize Tank before installing.

It is recommended to use plastic NPT male fittings with plastic female NPT fittings to avoid damaging the threads, metal thread fittings can crush the plastic threads.

1.375" hose can not be used with spouts on tanks

Can I hook more than one tank together?

Yes, you will need to check with a certified plumber to see what fittings and set-up will work best for your unit, remember to vent each tank.

I bought a fitting from my local hardware store and it won't fit.

Be sure you are using NPT fittings and getting the correct sizes. Do not over-tighten fittings as damage will occur.

National Pipe Threads (NPT)

Pipe sizes do refer to physical dimensions, but the plumbing industry standard for the sizes of pipe is not always as straight-forward as measuring the pipe. Measuring the pipe will oftentimes mislead you into choosing the wrong pipe, so do take care. The "pipe thread size" as shown in column 3 of the table below is measured and based on the inside of the pipe. But, to actually determine the size of a pipe, the outside diameter of each pipe or fitting must be measured and compared to the table for size identification. For example, a 3/4" NPT pipe thread has an outside diameter of 1.050 inches. Each thread size has a defined number of threads per inch (TPI). The 3/4" NPT pipe thread has 14 threads per inch. Both the TPI (threads per inch) and OD (outside diameter) of the thread are required for positive identification of thread size because several sizes have the same TPI.

Male threads: Measure the outside diameter of the large portion of the thread at "A"; Find figure nearest this dimension in column 1 or 2 of chart. The dimension in column 3 will be your nominal pipe thread size.

Female Threads: Measure top diameter of thread at "B"; Find figure nearest this dimension in column 1 or 2 of chart. The dimension in column 3 will be your nominal pipe thread size.

Q."What does 'nominal' mean?"

A. Nominal is the term used to describe pipe and fitting measurements in plumbing. Nominal refers to the inside diameter of the pipe which varies by wall thickness of the pipe.

Q."Ok, so IPS pipe sizing isn't actually a dimension. So what about the fittings?"

A. Pipe fittings are "sized" by the "size" pipe they fit. So, for example, a 1/2" IPS fitting would fit 1/2" IPS pipe.

National Pipe Threads (NPT) have tapered threads. These are the most common threads used for general purposes. NPT threads are designed with a 60 degree thread angle, and are used for joining and sealing pipe to fittings in low pressure air or liquids and also mechanical applications. The tapered thread is 3/4" over one foot of length. Tapered threads are deeper at the end of the pipe and are increasingly shallower the further they are from the end of the pipe. The taper on the pipe only allows the pipe to screw inside the fitting until it is forced to stop because of the taper. The distance the pipe can be screwed into the fitting is specified by the ANSI standard. After tightening with a wrench the threads may have slight spaces between the pipe and fitting which could cause a leak so a pipe sealant must be used to ensure any gaps are filled.

The Dry-seal thread (NPTF) also have tapered threads. NPTF threads are used when the application is such that pipe sealing compounds may fail due to higher heat or pressure than normal NPT threads can withstand. The threads are designed to seal mechanically by slightly, but sufficiently, crushing the threads when tightened with a wrench. This allows for joining the pipe and fitting without sealants.

The NPT and NPTF threads can be interchanged if sealants such as PTFE tape or suitable pipe joint compounds are used. None of the other thread standards are fully interchangeable (GHT, NST, BSPT, NPSI, etc.) Female NPT threads can be designated as "FPT" or

"FIP" and male NPT threads can be designated as "MPT" or

"MIP".

National Standard Free-Fitting Straight Mechanical Pipe Threads (NPSM) have straight threads which are only used for joining. A washer or gasket is needed to seal this type of threaded connection.

There are also three less common thread types used in the plumbing industry. The Garden Hose Thread (GHT) and the Fire Hose Thread (NST) have coarse threads. The seal is made with a gasket or washer and are used mainly for attaching (joining) hoses to valves quickly, without the use of a wrench. The British Standard Taper Pipe Thread (BSPT) has a 55 degree thread angle (NPT are 60 degree) and is used internationally as a standard thread for joining steel pipes.

~ Installing & Bracing ~

|

|

Can I install the tank under the trailer?

Do I need to brace the water tank, the wall looks bowed?

Can I stack the water tanks on top of each other?

No, do not place anything on the tanks, if you need to stack the tanks you will need a weight bearing shelf between them.

Sanitize each tank prior to use to remove any debris from the manufacturing process. Tanks are made in a warehouse so maybe dusty or scuffed, this does not effect the use or safety of the tank, wipe with a damp cloth to remove surface dust or scuffs.

1. Prepare a chlorine solution using one gallon of water and a ¼ cup of household bleach (5% sodium hypochlorite solution)

** DO NOT USE FRESH SCENT OR ANY SCENT ENHANCED BLEACH **

Never mix bleach with ammonia or other cleaners.

Open windows and doors to get fresh air when you use bleach.

With tank empty, pour chlorine solution into tank. Use one gallon of solution for each 15 gallons of tank capacity.

2. Complete filling of tank with fresh water.

3. Allow to stand for three (3) hours

4. Drain and flush with potable fresh water.

Any residual chlorine odor will dissipate naturally.

~ Monitor Panels & Water Tank Probes ~

RV Monitor Panels allow you to monitor the amount of fluid in your water and waste tanks along with the battery power level. Typically only one monitor panel (2 tank or 3 tank) is needed per vehicle/unit and 4 Probes per tank.

To check fluid levels, press and hold the button designated for the tank and read the level indicators on the panel. Sometimes, residue on the sides of a tank, or water with a low mineral content will give a false reading. Check the levels occasionally when you are sure of a tank’s contents and compare it to the reading on the monitor panel.

Class A Customs currently offers three styles of RV Water Tank Monitor Panels

All styles require a 12 volt power supply - do not hook to any other power supply or damage will occur.

Monitor Panel Includes the Harnesses - probes are sold separate

Customer will need to provide the wiring going from the harness to the Monitor Panel

For Step-by-Step Photos visit our Blog Post Water Tank Monitor Probes

Problem: No lights on panel when switch is pushed.

Make sure B+ wire (Red) has 12 Volt DC Connected.

Make sure Ground wire (White) is connected to panel.

Problem: Displays false reading on tank(s)

Verify that levels in tank(s) do not match display.

Swap tank connections on panel and reset tank functions to see if problem has also changed over to another tank or is still in same tank(s).

Check probe placements in tank(s) to assure proper placement and installation.

Verify wiring is properly installed, no shorts and grounded correctly.

~ Water Pumps ~

12 volt Power Supply ONLY 110/115/220 volt such as in a house or generator will damage the unit

Both pumps are on-demand, they turn on only when the pressure in the water line goes down (when you open faucet)

Strainer must be used on the pump before allowing water to enter pump

CLASS A CUSTOMS BLACK TANK Used for Human Waste or Gray Water - DO NOT use for fresh or drinking water

MADE WITH Recycled Medium Density Polyethylene (MDPE) Resin

SEAMLESS One piece construction, no seams to burst

RESISTANT Stain, Corrosion and Rust Resistant

Tanks are made in a warehouse light scratching, scuffs, dust, and outlet glue may be present on tanks and does not affect performance of tank.OEM PART No retail box - no install instructions Have a certified technician install all parts to prevent product damage and personal injury

INSTALLED OUTLET

3” ABS Female Pipe - outlet can not be moved

INLET & VENT INSTALLATION

Black Water Tanks only come with the outlet the end user will determine where the inlet and vent will need to be placed and install.

Grommet or Uniseal will secure inlet/vent pipe with no adhesives needed. Use correct size hole saw bit in order to drill a hole in the tank and place Grommet or Uniseal in hole, piping is then placed in fitting with no glues or adhesives necessary.

Included are a few short videos displaying the grommet installation process.

Brace tank to prevent tank from moving during transit

Do Not hang by ratchet strap, this is too thin and will not adequately support tank.

Do Not place weight on tank, if you need to stack the tanks you will need a weight bearing shelf between them.

Due to the variety of installations we do not carry brackets or bracing systems.