Class A Customs is not the manufacturer of this item, you would need to contact Flojet, information is on the paperwork provided with pump.

Flat Rate Economy Shipping to the lower 48 Contiguous US Only by USPS Mail

Features & Specifications:

Made by Flojet Model#03526144 / R3526144*

12 volt - You can not put this in a house or plug into a wall - 110/115/220 volt will damage the unit.

4.4 Amp Draw @ 10 PSI

7.5 Amp Draw @ 50 PSI

2.9 Flow GPM

Max PSI 50 Pressure Switch

Built-in Bypass Less Pulsation

Self-priming up to 9 feet suction lift

Run Dry Pump able to run dry without damage

Soft Noise Absorbing Mounts

Snap–in Port Fittings - ½” Fittings included, see photos

CAN NOT be used with accumulator tank

Corrosion Resistant Materials

Meets ISO 8846 (Ignition protection)

Motor Permanent Magnet, Ball Bearing

Pump Three chamber diaphragm design

Totally Enclosed CE Models are fully suppressed.

Includes a Flojet Strainer Model # 01740300

Fittings Included:

2 - 20381000 Pump Port x ½” Male Qest. Straight

1 - 20381009 Pump Port x ½” Hose Barb 90 deg. Elbow

1 - 20381002 Pump Port x ½” Hose Barb Straight

CAUTION: Pump surface will get hot to the touch if operated for extended periods of time under pressurized conditions. Pump will shut off to cool down.

INSTALLATION INSTRUCTIONS

Step 1: Remove shipping plugs from pump ports. Some water from factory testing may spill out.

Step 2: Connect fitting supplied with the pump the the RV’s plumbing. Use ½” I.D. Flexible hose as shown. Use hose clamps on the slip-on barb hose connectors.

Step 3: Slide rubber mounts fully into mounting tracks.

Step 4: Mount plumbing vertically, with the pump head down or horizontally in an accessible location. If mounting vertically, motor up, attach mounts first then pump head mounts, while supporting weight of pump.

Step 5: Install inlet A and Discharge B port connectors. Firmly push clips C forward to lock port connectors in place.

Step 6: Install a Flojet Strainer in an accessible location (for cleaning and inspecting) before the pump between the tank and the water pump. This strainer or equivalent is required for pump warranty to be valid.

WIRING INSTRUCTIONS

12 volt - You can not put this in a house or plug into a wall - 110/115/220 volt will damage the unit.

Step 1: Use 14 gauge stranded wire to 20', 12 gauge to 50' from power source.

Step 2: Use a 10-15 amp rated on-off switch on the (+) positive (red) motor lead.

Step 3: Install a 10 amp fuse protection on the positive lead.

WARNING:

BEFORE SERVICING PUMP, TURN OFF PUMP AND DRAIN WATER FROM SYSTEM

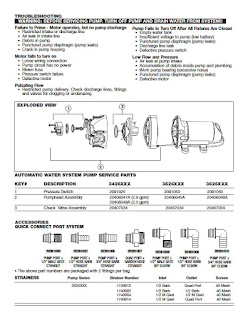

TROUBLESHOOTING

Failure to Prime - Motor operates, but no pump discharge

• Restricted intake or discharge line

• Air leak in intake line

• Debris in pump

• Punctured pump diaphragm (pump leaks)

• Crack in pump housing

Motor falls to turn on

• Loose wiring connection

• Pump circuit has no power

• Blown fuse

• Pressure switch failure

• Defective motor

Pulsating Flow

• Restricted pump delivery. Check discharge lines, fittings

and valves for clogging or undersizing

Pump Fails to Turn Off After All Fixtures Are Closed

• Empty water tank

• Insufficient voltage to pump (low battery)

• Punctured pump diaphragm (pump leaks)

• Discharge line leak

• Defective pressure switch

Low Flow and Pressure

• Air leak at pump intake

• Accumulation of debris inside pump and plumbing

• Worn pump bearing (excessive noise)

• Punctured pump diaphragm (pump leaks)

• Defective motor

Winterizing Sanitizing

SYSTEM CARE AND MAINTENANCE

Allowing water to freeze in the system may result in damage to the pump and plumbing system.

Non-Toxic antifreeze for potable water may be used with Flojet pumps. Follow manufacturer's recommendations.

Refer to coach or equipment manufacturer's instructions for their specific winterizing and drainage procedures.

Do not use automotive antifreeze to winterize potable water systems. These solutions are highly toxic and may cause serious injury or death if ingested.

1. Drain the water tank. Open tank drain valve and plumbing drain valves if applicable. You may use the pump to drain the tank by opening all the faucets in the system. Allow the pump to operate until the tank is empty. Do not operate the pump more than 15 minutes continuously.

2. Open all faucets and flush the toilet to purge all the water from the pump and the plumbing system. Run the pump until no water is coming through the faucets. Turn power to the pump off. Be sure that all the water from the drain lines are drained.

3. Remove quick connect inlet and outlet fittings from the pump and turn the pump on to pump out remaining water from the pump head. Be sure to have a catch pan or a rag under the pump to prevent water from spilling onto the RV. Turn the pump off once the plumbing is empty. Leave the fittings disconnected from the pump until the system is ready to be used again. Make a note on your tank filler that the plumbing is not connected.

4. Be sure that all faucets are left open to protect against damage to the plumbing. Portable water systems require periodic maintenance to deliver a consistent flow of fresh water. Depending on use and the environment the system is subject to, sanitizing is recommended prior to storing and before using the water system after a period of storage. Systems with new components, or ones that have been subjected to contamination, should also be disinfected as follows:

NOTE: The sanitizing procedure is in conformance with the approved procedures of RVIA ANSI A119.2 and the US Public Health Service.

1. Use of the following methods to determine the amount of common household bleach needed to sanitize the tank.

1. A) Multiply “gallons of tank capacity” by 0.13; the result is the ounces of bleach needed to sanitize the tank.

1. B) Multiply “Liters of tank capacity” by 1.0; the result is the milliliters of bleach needed to sanitize the tank.

2. Mix into solution the proper amount of bleach within a container of water

3. Pour the solution (water/bleach) into the tank and fill the tank with potable water.

4. Open ALL faucets (hot and cold) allowing the water to run until the distinct odor of chlorine is detected.

5. The standard solution must have four (4) hours of contact time to disinfect completely. Doubling the solution concentration allows for contact time of one (1) hour.

6. When the contact time is completed, drain the tank. Refill with potable water and purge the plumbing of all sanitizing solution.

WARRANTY

FLOJET warrants this product to be free of defects in material and/or workmanship for a period of two years after purchase by the customer from FLOJET. During this two warranty period, FLOJET will at its option, at no charge to the customer, repair or replace this product if found defective in material or workmanship, with a new or reconditioned product, but not to include costs of removal or installation. This is only an overview of our Limited Warranty. If you would like a copy of our warranty, please call or write FLOJET.

RETURN PROCEDURE

Prior to returning any product to FLOJET, call customer service for an authorization number. This number must be written on the outside of the shipping package. Place a note inside the package with an explanation regarding the reason for return as well as the authorization number. Include your name, address and phone number. Class A Customs is not the manufacturer of this item, you would need to contact Flojet, information is on the paperwork provided with pump.

Class A Customs

1130 County Road 6 West

Elkhart, IN 46514

Call Us: (574) 206-0101